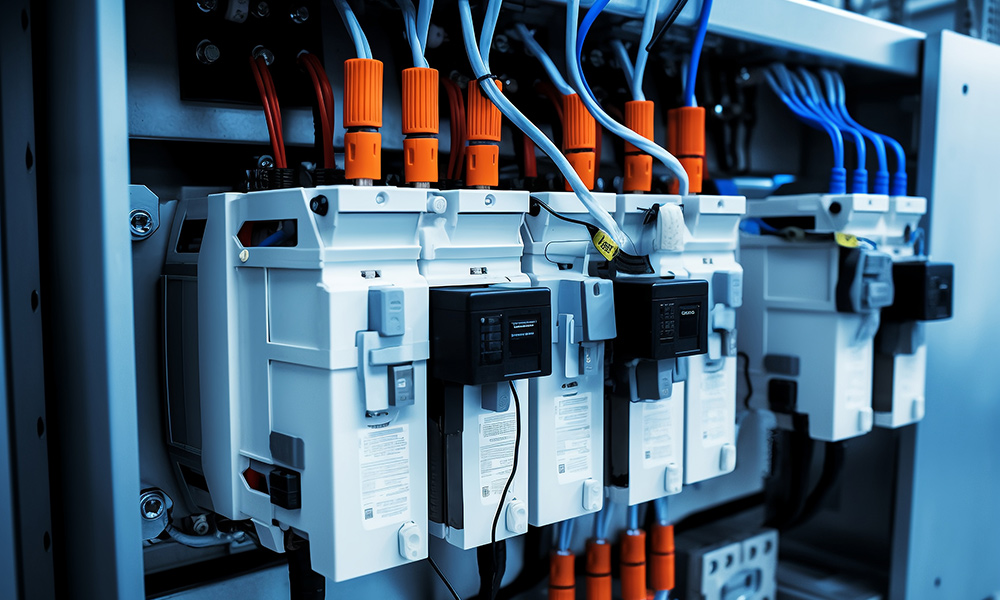

The component-level rapid shutdown PLC control box is a device that cooperates with the component-level fire rapid shutdown actuator to form the photovoltaic DC side quick shutdown system, and the device conforms to the American National Electrical Code NEC2017&NEC2020 690.12 for rapid shutdown of photovoltaic power stations. The specification requires that the photovoltaic system on all buildings, and the circuit beyond 1 foot (305 mm) from the photovoltaic module array, must drop to below 30 V within 30 seconds after the rapid shutdown start; The circuit within 1 foot (305 mm) from the PV module array must drop to below 80V within 30 seconds after the fast shutdown start. The circuit within 1 foot (305 mm) from the PV module array must drop to below 80V within 30 seconds after the rapid shutdown start.

The component-level fire rapid shutdown system has automatic power off and reclosing functions. On the basis of meeting the rapid shutdown function requirements of NEC2017&NEC2020 690.12, it can maximize the power generation of the photovoltaic power generation system and improve the power generation rate. When the mains power is normal and there is no emergency stop demand, the module level fast shutdown PLC control box will send a closing command to the fast shutdown actuator through the photovoltaic power line to connect each photovoltaic panel; When the mains power is cut off or the emergency stop is started, the component-level rapid shutdown PLC control box will send the disconnection command to the rapid shutdown actuator through the photovoltaic power line to disconnect each photovoltaic panel.

A component-level rapid shutdown PLC control box is a device used in photovoltaic (PV) systems to facilitate rapid shutdown functionality at the component level. Rapid shutdown is a safety requirement aimed at reducing the risk of electrical hazards during emergency situations or maintenance activities.

Here are some key points about a component-level rapid shutdown PLC control box:

Purpose: The primary purpose of a component-level rapid shutdown PLC control box is to enable rapid shutdown functionality in a PV system. Rapid shutdown refers to the ability to quickly de-energize the DC circuits of the PV system, reducing the voltage at the source to a safe level during emergency events or when maintenance work is required.

PLC (Programmable Logic Controller): A PLC is a digital computer used to control and automate various processes. In the context of a rapid shutdown control box, a PLC is employed to monitor and control the rapid shutdown functionality of the PV system. It receives signals from external devices and initiates the shutdown process.

Control Box: The control box contains the necessary circuitry, components, and interfaces to implement the rapid shutdown functionality. It typically includes inputs for receiving signals from external devices, such as rapid shutdown initiators or emergency shutdown switches, and outputs to control the shutdown of the PV system.

Component-Level Shutdown: A component-level rapid shutdown system involves the shutdown of specific components or sections of the PV system, rather than shutting down the entire system. This allows emergency responders or maintenance personnel to work safely on specific areas without being exposed to high voltages.

Compliance with Codes and Standards: Rapid shutdown requirements are specified in electrical codes and standards, such as the National Electrical Code (NEC) in the United States. A component-level rapid shutdown PLC control box should comply with these regulations to ensure the PV system meets the necessary safety requirements.

Integration: The component-level rapid shutdown PLC control box is integrated into the overall PV system’s control and monitoring infrastructure. It communicates with other system components, such as inverters or monitoring systems, to coordinate the rapid shutdown process.

It’s important to consult with a qualified electrician or PV system designer to ensure the proper selection, installation, and integration of a component-level rapid shutdown PLC control box. Compliance with local electrical codes and regulations should be followed to ensure the safety and reliability of the PV system.

Welcome to consult us for your special demand on Rapid Shutdown PLC Control Box

Post time: Aug-10-2023

Solutions

Solutions Support

Support News

News About Us

About Us